Bottle Washing Plant

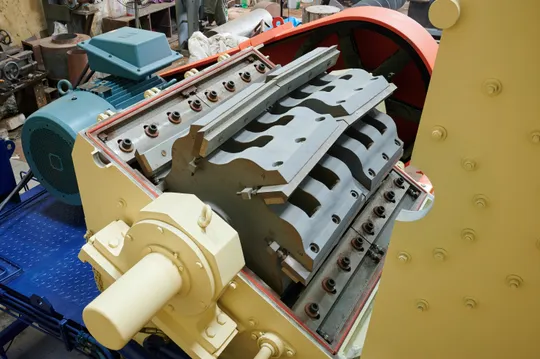

Grinder

Capitalizing on our rich industrial experience, we hold specialization in providing a wide range of Grinder. Made using finest grade raw material, it comes in different sizes and specification to fulfill the requirements of various clients.

Offered range of Grinder is highly appreciated and demanded in the market for their special features like robust construction, fine finish, durability and optimum performance.

We always try to deliver a quality approved range and within a promised time period.

Features:- High tensile strength

- Durable standard

- Abrasion resistance

Bale Breaker with Belt Conveyor

PET bottles to be recycled are normally received by the processing units in the form of bales to reduce the transport volume and cost. Since the PET bottles are compressed in hydraulic presses while making bales, unbaleing manually is very difficult and consumes lot of labour. Labour dependency also affect the uniform flow of material in to the process. To overcome this problem ,bale breaker is installed at the beginning of the recycling unit.

This consists of a horizontal belt conveyor driven by a speed controlled electric motor. The discharge end of the belt conveyor is mounted with a bale breaker which loosen the bale to suit the process requirement. Normally it handles PET bottles capacity ranging from 1000 kgs to 3000 Kgs per hour. This unit is made out of carbon steel.

Screw Conveyor

Twin screw conveyors are used to convey the PET bottles to the required elevation according to the process.

Normally these conveyors are installed in inclined position and driven by two individual motors.

It consists of a 'U' truff and two number rotating screws mounted inside the 'U' truff with bearing supports on both sides. This conveyor is made of carbon steel.

Label Scraper

All un removed labels from the bottles are passed through label scraper wherein labels still sticking to the bottles are separated.

Since the labels are made out of PVC it has to be separated to avoid contamination of PVC with PET.

This consists of a heavy cylindrical housing in which specially designed rotor is rotating. The rotor is driven by a electric motor.

The capacity of this machine ranges from 500 Kgs per Hr to 1500 Kgs/hr.

Bottle Washers

Bottle Washer With Hot Air Dryer

- Bottle Size : 100 ml / 200 ml / 500 ml / 1 Ltr

- Working Height : 850 mm . ( Adjustable )

- Washing Capacity : 1500 BPH / 2400 BPH

- Tank : Adequate

- Washing Cycle : 5 Different Cycles Detergent Hot Water Hot Air

- Body : S.S.304

- Operating : Fully Automatic with digital Display

- Additional Features : Water Recycling

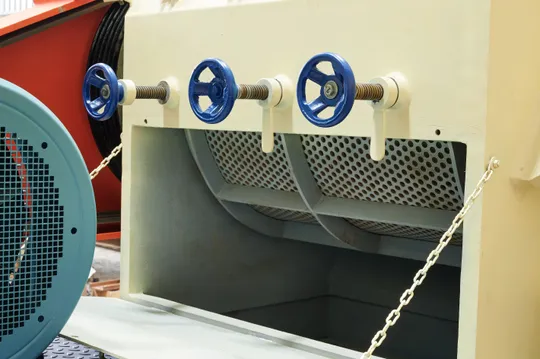

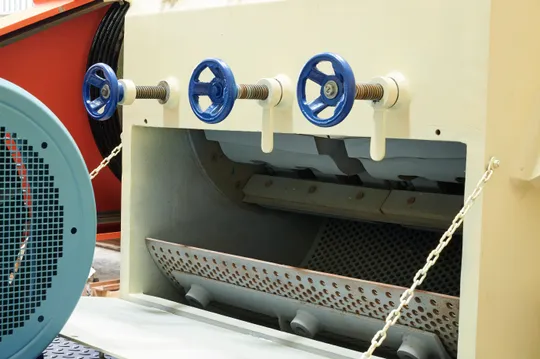

Trommel

Our trommel, also known as rotary screen, is an essential unit which is used mainly in the mineral and solid-waste processing industries. It consists of a perforated cylindrical drum which is normally elevated at an angle at the feed end.

Physical size separation is achieved as the feed material spirals down the rotating drum, where the undersized material smaller than the screen apertures passes through the screen, while the oversized material exits at the other end of the drum.

Features:- Range of application

- Pet waste

- Mineral processing

- Other applications

.webp)

.webp)

.webp)

.webp)

.webp)