Our Equipments

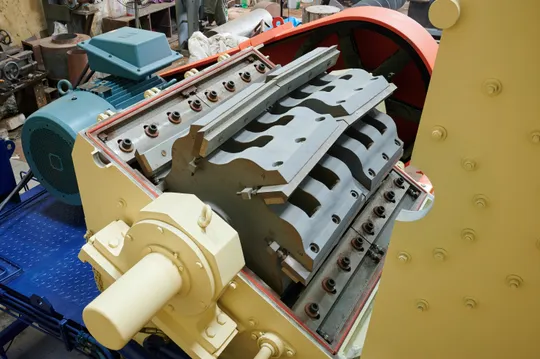

Grinder

Grinders are used to cut the PET Bottles / Scraps to the required size.

It comes with wet or dry processing. We supply different models as per the capacity requirement. We manufacture force feed Grinders in which the materials are forced in to the grinding chamber by screw feeders. This is more efficient machines. It is made out of carbon steel

Screw Conveyor

Twin screw conveyors are used to convey the PET bottles to the required elevation according to the process. Normally these conveyors are installed in inclined position and driven by two individual motors. It consists of a U truff and two number rotating screws mounted inside the U truff with bearing supports on both sides. This conveyor is made of carbon sheet.

SS Screw conveyor with round body in used for conveying PET Flakes.

Belt Conveyors are used for sorting the material.

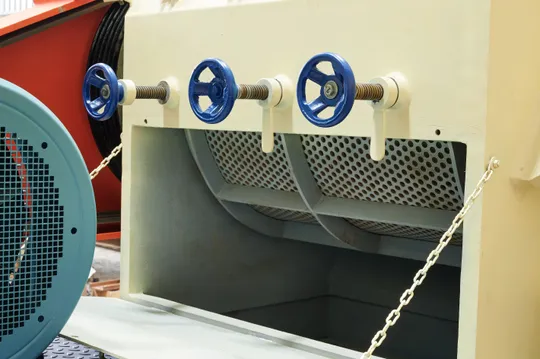

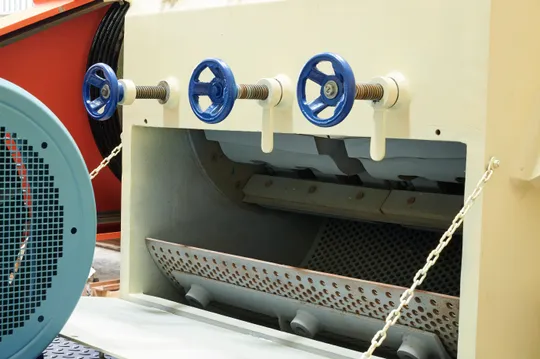

Label Scraper

All un removed labels from the bottles are passed through label scraper where in labels still sticking to the bottles are separated. Since the labels are made out of PVC it has to be separated to avoid contamination of PVC with PET.

This consists of a heavy cylindrical housing in which specially designed rotor is rotating. The rotor is driven by a electric motor. The capacity of this machine ranges from 500 Kgs per Hr to 5000 Kgs / hr. This machine can be supplied for wet and dry application.

Bottle Washers

It is used for pre washing the bottles to be recycled.

It consists of a rotating drum mounted on 3 / 4 sets for driving and supporting rollers. Hot water is injected into the rotating drum, when the bottles are soaked in Hot water while travelling it gets cleaned and the dirty water is drained in the perforated area. The contaminated water is recycled after filtration.

Trommel

It consists of a perforated rotary drum rotating at the slow speed. It is used for removing foreign materials from the PET Bottles. It can be supplied both wet and dry applications. It is mounted either Horizontal or inclined. It is made out of Carbon sheet.

Gravity Separator

This Equipment is used to remove the oating material like PP / PE from the PET. It is a Horizontal tank with conical at the Bottom. Sink material (PET) is conveyed by the Bottom screw and the oat material is conveyed by the series of Vaned drums and discharged through the perforated screw conveyor. This is made out of stainless steel.

Horizontal Rinsing Tank

Rinsing Tanks offered comes in quality construction finish with choice of different dimensions to pick from.

Features:

- Container comprising wall material of 304 grade

- Sealing material support comprising EPDM

Specifications:

- Suitable for food grade and liquid hazardous goods

- Can handle goods with density less than or equal to 2.0

- Butterfly outlet valve support

- Comes with safety valve pressure setting of 0.21bar

Hot Wash Tanks

Hot wash tanks are vertical cylindrical type with bottom conical, suitable for discharging from the bottom. The akes are put in the vessel with Hot water of 85-900 Caustic solution /Flakes are added as a cleaning medium in the tank. The tank is tted with Agitator for proper washing. This Equipment is supplied with MOC of SS or MS. Normally it functions on batch type.

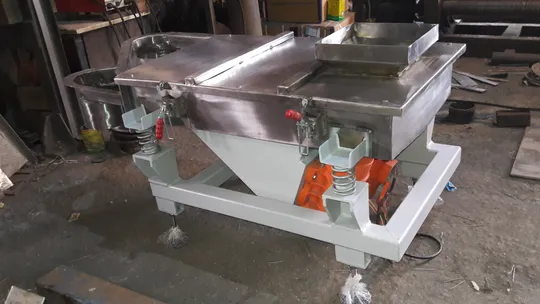

Vibrating Screen

It is used for separating the nes and over sizes from the washed akes. It is a Horizontal Vibrating machine tted with 2 Nos. vibrating motors. The screen size can be changed as per requirement.

Zig Zag Assembly

It is used to separate the water and material after washing. It also cleaned the akes. It comes in the capacity ranging from 500 Kgs to 5000 Kgs per hour. It is made out of stainless steel.

Horizontal Spin Drier

It is used to separate the water and material after washing. It also cleaned the akes. It comes in the capacity ranging from 500 Kgs to 5000 Kgs per hour. It is made out of stainless steel.

Pneumatic Drier

It is used to remove the moisture from the washed akes. It consists of blower, Heat exchanger, Pneumatic conveying arrangement. When the Hot air comes in contact with the material it gets dried. It is made out of stainless steel.

Bale Breaker with Belt Conveyor

PET bottles to be recycled are normally received by the processing units in the form of bales to reduce the transport volume and cost. Since the PET bottles are compressed in hydraulic presses while making bales, un baleing manually is very difficult and consumes lot of labour.

Labour dependency also affect the uniform ow of material in to the process. To overcome this problem bale breaker is installed at the beginning of the recycling unit. This consists of a horizontal belt conveyor driven by a speed controlled electric motor.

The discharge end of the belt conveyor is mounted with a bale breaker which loosen the bale to suit the process requirement. Normally it handles PET bottles capacity ranging from 1000 kgs to 5000 kgs per hour. This unit is made out of carbon sheet.

Turbo Washer

It is used for cleaning the Hot washed Flakes. In this Equipment PET Flakes are cleaned due to high friction and attrition. It consists of a vertical body and rotor rotating at high speed. Material is fed through feed screw uniformly. It is made out of carbon steel.

Label Separator

This Equipment is used to remove separated labels from the bottles which comes from label scraper. It consists of a inclined Cylindrical Drum rotated at a slow speed. One end is tted with a blower to blow the labels and the other end is tted with a Hopper to collect the labels. It is made art of carbon sheet.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)